West System Filler Powders 402 - 410

Add West System fillers to thicken epoxy for specific applications

For bonding or fairing

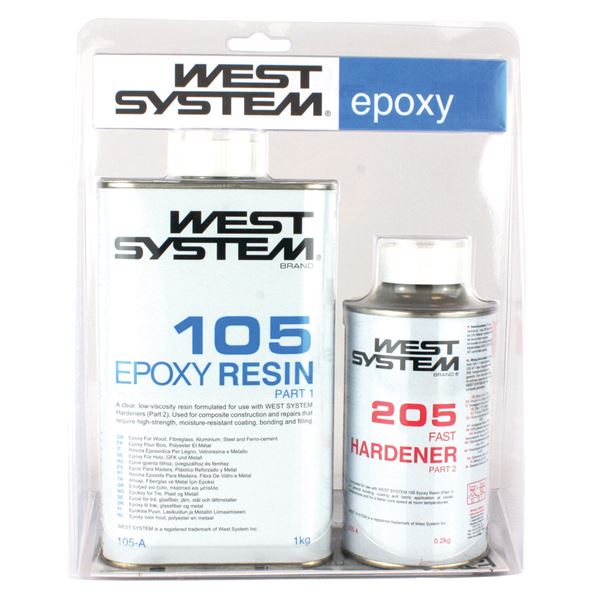

Use with 105 resin & hardeners

West System are the market leaders in epoxy resins.

Fillers are used to thicken the basic resin/hardener mixture for specific applications. Each filler possesses a unique set of physical characteristics, but they can be generally categorised as either adhesive (high-density) or fairing (low-density).

Adhesive filler mixtures cure to a strong, hard-to-sand plastic useful in structural applications like bonding, filleting and hardware bonding. Any of the WEST SYSTEM adhesive fillers are suitable for bonding situations.

Fairing filler mixtures cure to light, easily sandable material that is generally used for cosmetic or surface applications like shaping, filling or fairing.

As a rule, it is better to use higher-density fillers when bonding higher-density materials such as hardwoods and metals.

Filler Types:

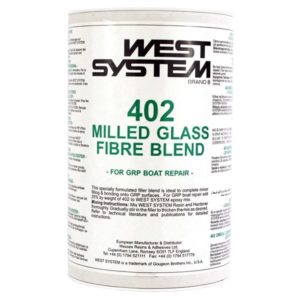

402 – Milled Glass Fibre Blend: This specially formulated filler is ideal to complete minor filling & bonding onto GRP surfaces. For GRP boat repair add 25% by weight of 402 to West System epoxy mix. Colour: White.

403 – Microfibres Adhesive Filler: A blend of cellulose cotton fibres, used as a thickening additive for bonding applications. Epoxy thickened with microfibers provides good wetting out of the substrates and excellent gap-filling properties. Add 4% to 16% by weight to West System epoxy mix. Colour: Off-White.

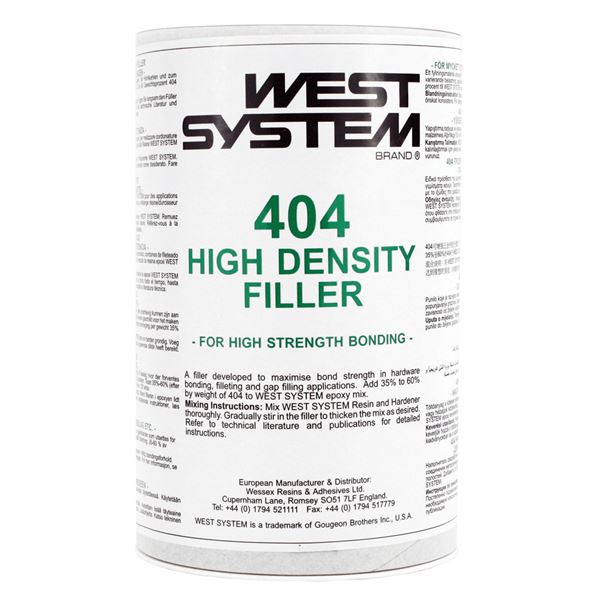

404 – High Density Filler: A filler designed to maximize bond strength in hardware bonding where high cyclic loads are anticipated. It can also be used for filleting and gap-filling applications. Add 35% to 60% by weight, depending on the viscosity required. Colour: Off-White.

405 – Filleting Blend: Consists of a mix of cellulose fibres and other fillers for use in filleting applications when a naturally finished interior is intended. Alcohol or water based stains may be added to adjust the colour. Add 15% to 25% of Filleting Blend by weight. Colour: Tan.

406 – Colloidal Silica: General purpose thickening additive suitable for bonding, gap-filling and filleting. 406 can be used to prevent resin flow on vertical and overhead surfaces and to control the viscosity of the epoxy. Add 3% to 8% by weight to the resin/hardener mix. Colour: Off-White.

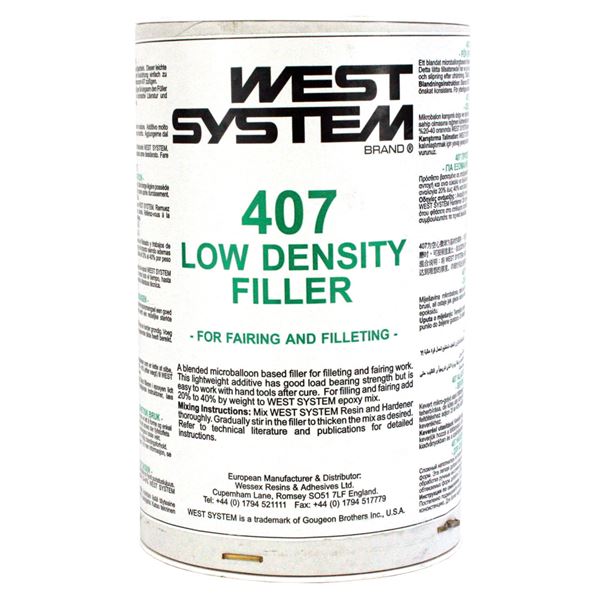

407 – Low Density Filler: A blended microballoon-based filler to make fairing putties which are easy to sand but remain strong on a strength-to-weight basis. Add 20% to 40% by weight to mixed epoxy. Colour: Reddish-Brown.

409 – Microsphere Blend: A pure white, blended microsphere based filler for filling and fairing GRP boats. This light weight additive has good load bearing strength but is easy to work with hand tools after cure. For filling and fairing add 10% to 25% by weight to mixed epoxy. Colour: White.

410 – Microlight: This low density filler is ideal for creating a lightweight, easily worked fairing compound, especially suited for large areas. Microlight holds a fantastic feather edge and is the easiest filler throughout the West System range to fair. Add between 7% to 16% by weight to mixed epoxy. Colour: Tan.

For any technical questions about product selection, health and safety or “how to” advice contact the West System technical support line on 01794 521111 or email [email protected]